龙门吊租赁

2019年起重机及相关设备报价?

2019年起重机及相关设备报价?

因市场价格波动,请填写手机号获取今日最新报价表。

因市场价格波动,请填写手机号获取今日最新报价表。

价格表:含配件价格及详细参数,方便您做对比决策。

价格表:含配件价格及详细参数,方便您做对比决策。

门座型式起重机

门座起重机桥架通过两侧支腿支承在地面轨道或地基上的桥架型起重机。具有沿地面轨道运行,下方可通过铁路车辆或其他地面车辆。可转动的起重装置装在门形座架上的一种臂架型起重机。门形座架的4条腿构成4个"门洞",可供铁路车辆和其他车辆通过。门座起重机大多沿地面或建筑物上的起重机轨道运行,进行起重装卸作业。门座呈""字形的起重机称半门座起重机,其运行轨道的一侧设在地面上,另一侧设在高于地面的建筑物上。

简史

门座起重机是随着港口事业的发展而发展起来的1890年,第一次将幅度不可变的固定式可旋转臂架型起重机装在横跨于窄码头上方的运行式半门座上,成为早期的港用半门座起重机随着码头宽度的加大,门座和半门座起重机并列发展,并普遍采用俯仰臂架和水平变幅系统。第二次世界大战后,港用门座起重机迅速发展为便于多台起重机对同一条船进行并列工作,普遍采用了转动部分与立柱体相连的转柱式门座起重机(图1[转柱式门座起重机]),或转动部分通过大轴承与门座相连的滚动轴承式支承回转装置,以减小转动部分的尾径,并采用了减小码头掩盖面(门座主体对地面的投影)的门座结构。在发展过程中,门座起重机还逐步推广应用到作业条件与港口相近的船台和水电站工地等处。

分类

按用途可分为3类:①装卸用门座起重机:主要用于港口和露天堆料场,用抓斗或吊钩装卸。起重量一般不超过25吨,不随幅度变化。工作速度较高,故生产率常是重要指标。②造船用门座起重机:主要用于船台、浮船坞和舣装现场,进行船体拼接、设备舣装等吊装工作,用吊钩作为吊具。最大起重量达300吨,幅度大时起重量相应减小。有多档起升速度,吊重轻时可提高起升速度。有些工作机构还备有微动装置,以满足安装要求。门座高度大者,可适应大起升高度和大幅度作业的要求,但工作速度较低,作业生产率不高。③建筑安装用门座起重机:主要用在水电站进行大坝浇灌、设备和预制件吊装等,一般用吊钩。起重量和工作速度一般介于前两类起重机之间。它具有整机装拆运输性好、吊具下放深度大、能较好地适应临时性工作和栈桥上工作等的特点。

组成

门座起重机有起升、回转、变幅和运行机构,前3种机构装在转动部分上,每一周期内都参加作业。转动部分上还装有可俯仰的倾斜单臂架或组合臂架及司机室。运行机构装在门座下部,用以调整起重机的工作位置带斗门座起重机(图2 [带斗门座起重机])还装有伸缩漏斗、带式输送机等附加设备,以提高门座起重机用抓斗装卸散状物料时的生产率。除电气保护装置外,还装有起重量或起重力矩限制器、起重机夹轨器等安全装置。

系统

门座起重机大多采用水平变幅系统。①重物和臂架系统各自的重心在变幅过程中几乎无垂直位移。其方法之一是靠增设活动平衡重来平衡臂架系统俯仰时的合成重心的升降变化这种方法布置较方便,工作也较可靠,应用广泛。方法之二是靠臂架系统的机构特性来保证变幅时合成重心的移动轨迹接近水平线,无活动平衡重。②所吊重物在变幅过程中沿着近于水平线的轨迹移动,可采用补偿法和组合臂架法。补偿法是通过特种储绳系统在变幅过程中自动收放相应起升绳,以补偿臂架升降造成的吊具垂直位移。组合臂架法是依靠组合臂架的机构特性保证臂端在变幅过程中接近水平移动。两种方法都得到广泛应用。

Gate type crane gate crane bridge on both sides by supporting leg on the ground track or foundation of bridge type crane.Orbits along the ground, below but by rail vehicles or other ground vehicles.Rotating lifting device is installed on the door form mounts a boom type of crane.Portal of mount 4 legs 4 "the gate", for rail cars and other vehicles pass.Mostly along the floor or building a door crane orbit, crane loading and unloading operations.Portal is "" glyph of half door crane, crane said one side of its orbit in the ground, on the other side is located in the top of a building above the ground.

Classification

It can be divided into three categories by appllication: (1) : a cargo door crane is mainly used for the port and the stocking yard in the open air, grab or hook load and unload.Lifting weight is generally not more than 25 tons, not changing with amplitude.Working speed is higher, so the productivity is often important index.(2) ship gate crane: mainly used in building berth, dock and fitting-out scene, carries on the hull splicing, equipment fitting-out, such as lifting work, with hook as a spreader.Maximum weight of 300 tons, at the time of the large range of weight reduced accordingly.How file hoisting speed, hoisting light lifting speed can be improved.Some work institutions also have micro devices, in order to meet the installation requirements.Door head high, can adapt to the requirement of large hoisting height and large assignments, but the work speed is low, work productivity is not high.(3) building installation with door crane: mainly used in hydropower station dam water, lifting equipment and fabrication, generally with the hook.Lifting weight and speed of work general interfaces between the former two types of crane.It has a good transport installation, hook down deep, can well adapt to the characteristics of temporary work and work on pier.

composition

Door crane hoisting, slewing, luffing and run institutions, three kinds of institutions on the rotating part, before every week period to participate in the work.The rotating part is also equipped with longitudinal tilting one-armed or combination of arm and the driver room.Line agencies, installed at the lower part of the door, in order to adjust the working position of crane with doumen crane (figure 2 [with doumen crane]) also equipped with a telescopic funnel, additional equipment such as belt conveyor, in order to improve the door crane grab when loading and unloading material productivity.In addition to electrical protection device, equipped with lifting weight or crane moment limiter, crane rail safety device.

system

Door crane is mostly adopt level luffing system.(1) the weight and their center of gravity in the process of the luffing boom system almost no vertical displacement.One of these methods is to rely on additional activities balance weight to balance the luffing boom system changes in the synthesis of center of gravity when it's convenient to make this approach to decorate, work more reliable, also widely used.Another approach is to rely on institutional characteristics of the boom system to ensure that the synthesis of center of gravity when the luffing movement closer to the horizon, no activities balance weight.(2) the lifting weights in luffing process along close to the trajectory of horizontal movement, can adopt compensation method and combination method of boom.Compensation method is automatically by the speci

拿不定主意?3分钟内闪速回电

拿不定主意?3分钟内闪速回电

立即填下您的电话,让选型工程师给您专业的建议

立即填下您的电话,让选型工程师给您专业的建议

价格表:含配件价格及详细参数,方便您做对比决策。

价格表:含配件价格及详细参数,方便您做对比决策。

热品推荐

热品推荐

HOME

HOME 5吨10吨20吨龙门

5吨10吨20吨龙门

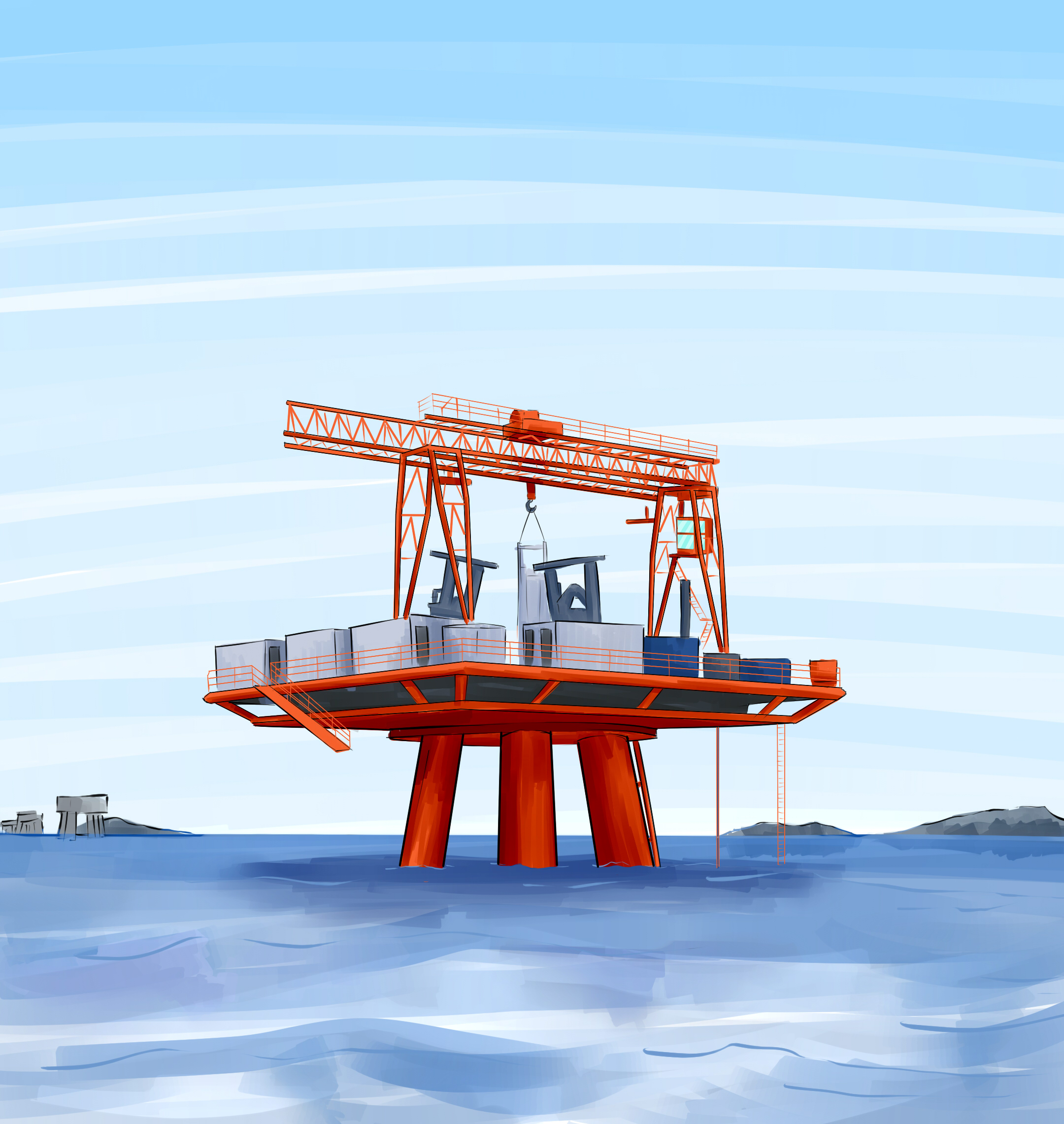

造船龙门吊

造船龙门吊

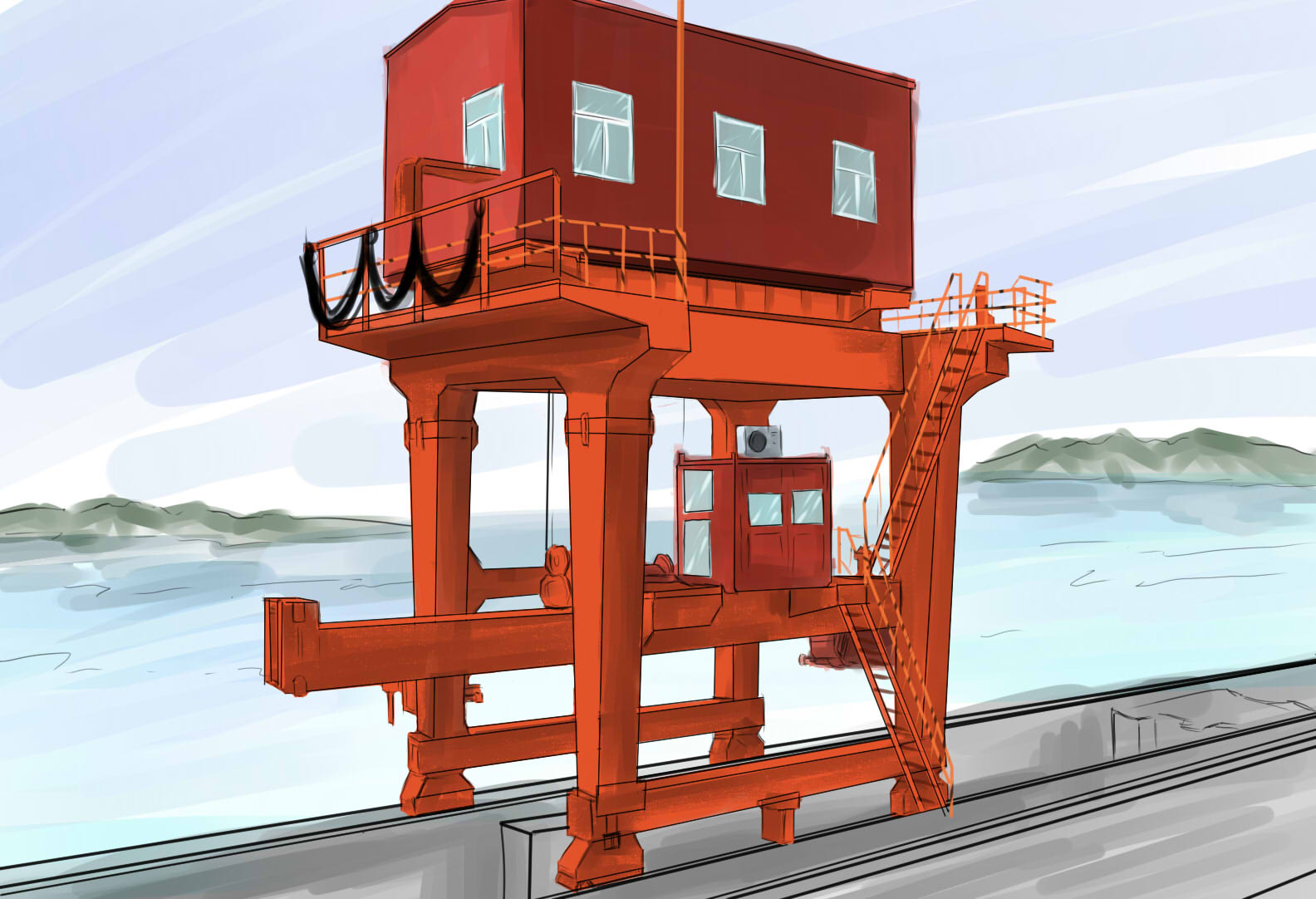

水电站门式起重

水电站门式起重

水电站坝顶门机

水电站坝顶门机

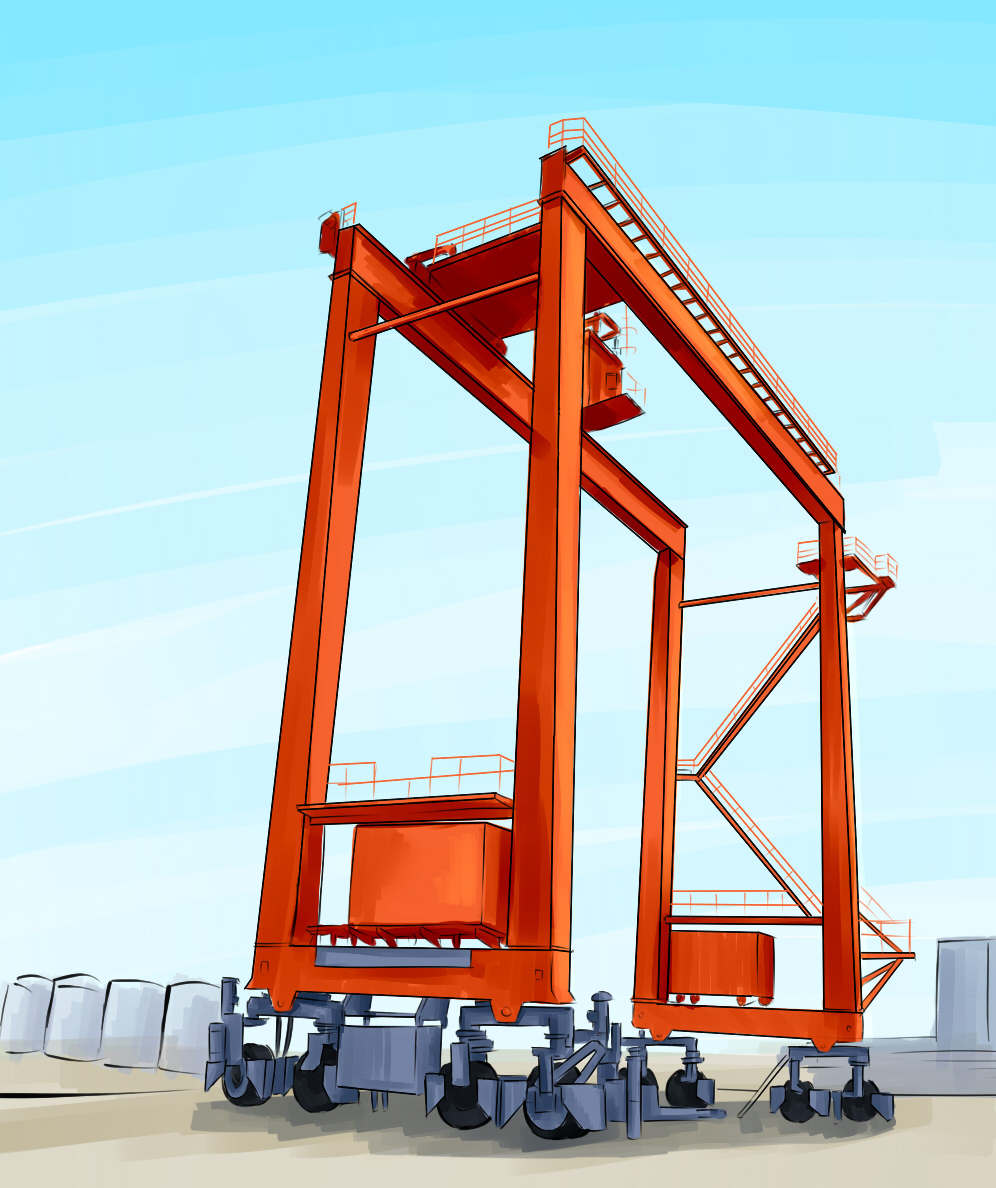

伸缩式集装箱吊

伸缩式集装箱吊

三角桁架式龙门

三角桁架式龙门

轮胎门机

轮胎门机